Pentomuls:

Due to increased usage of low quality fuel oil with high sulphur, asphaltene and vanadium content, power stations all over the world face both environmental and technical problems.

The incomplete combustion of the fuel oil as well as the vanadium and sulphur content cause deposits and corrosions in all parts of the boiler and excessive emissions of solids (particulates) and sulphur trioxide

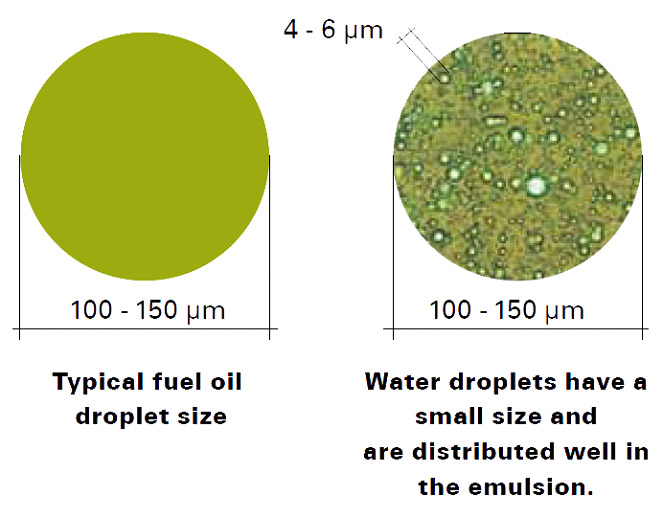

PentoMuls® allows the on-line production of a stable water-in-oil emulsion. Firing an emulsion has a great impact on the boiler:

Due to the secondary atomization, the fuel oil burns a great deal faster and much more completely. The result is a compact, short flame with a good temperature distribution, therefore much less nitrogen oxide (NOx) and sulphur trioxide (SO3) is generated.