Pentomag 4450:

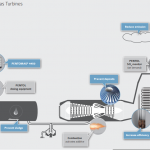

In a gas turbine that burns fuel-oil or residual fuel, ashes of the metallic salts are formed that come out with the gases of the combustion. This formation of ashes is INEVITABLE as the oil contains Sulphur, vanadium, sodium, potassium and other metals. These residuals adhere to the surfaces forming deposits and causing corrosion, reducing the useful life of gas turbines. These deposits depend fundamentally on the humidity and the temperature of the gas and are corrosive in nature. The volume of the deposits formed are directly related to the content of sludge in the fuel and their physical-chemical nature of these deposits.

The corrosion in the gas turbines is mainly located in the combustion chamber and is provoked by two principal causes:

- Formation of sodium vanadates of low fusion point that are corrosive. These compounds are formed as the fuel contains Vanadium (V) and Sodium (Na).

- Formation of sodium sulphate (a compound corrosive at high temperatures) will be formed independently of the fuel oil sulphur content. Despite the low sodium content of the fuel-oil a sulphur content below 0,1% is enough to form corrosive compounds.

Beginning at fuel delivery to the plant and ending with the gases emitted and waste materials treated after combustion.

PentoMag 4450 is designed to fulfill the following goals:

- Eliminate disintegration of organic sludge in the fuel tanks of the refinery, the fuel trucks and the tanks in the plants

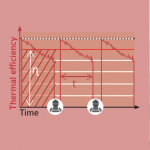

- Reduce fouling in gas turbine and recovery boiler

- Neutralize vanadium deposits and corresponding corrosion effects

- Reduction of maintenance time

- Improve combustion of the fuel with catalytic action

- Reduce wastewater generation.